Core Manufacturing Services Portfolio

our steps

Core Manufacturing Services Portfolio

Step 01

Comprehensive Feasibility Studies for Manufacturing Ventures

Our Feasibility Study Services provide the analytical foundation for informed investment decisions in manufacturing projects across diverse sectors and market conditions. We conduct detailed assessments that encompass financial viability, technical feasibility, operational requirements, and market positioning considerations that determine project success probability. The Methodology for Our Feasibility Studies begins with comprehensive market research that analyzes demand patterns, competitive landscapes, regulatory requirements, and growth projections specific to the target market and industry sector. This market analysis incorporates both quantitative data analysis and qualitative insights gathered through stakeholder interviews, industry expert consultations, and regional market assessments. Technical Design Viability Assessment addresses the engineering and technological considerations that influence project implementation success. Our technical analysis encompasses facility design requirements, equipment specifications, production process optimization, and quality control system development that ensure operational efficiency and product quality standards.

Financial Modeling and Return On Investment Analysis provide detailed projections of project costs, revenue potential, cash flow patterns, and profitability metrics that enable informed investment decisions. Our financial analysis incorporates sensitivity testing, scenario planning, and risk assessment methodologies that account for market volatility and operational uncertainties. Risk Mapping and Mitigation Planning identify potential challenges and develop comprehensive strategies for addressing implementation risks, operational challenges, and market uncertainties. Our risk assessment encompasses technical risks, market risks, regulatory risks, and financial risks that could impact project success. The Final Recommendation Report synthesizes all analytical components into actionable recommendations that guide investment decisions and implementation planning. Our reports provide clear guidance on project viability, implementation requirements, and success factors while addressing specific client concerns and objectives. Our competitive advantage in feasibility study delivery stems from the integration of proprietary artificial intelligence tools and sectoral benchmarking databases that enable accelerated analysis and enhanced accuracy. This technological integration enables us to deliver comprehensive feasibility studies within five days while maintaining analytical rigor and practical applicability.

Step 02

Turnkey Project Implementation Excellence

Our Turnkey Project Implementation Services address the complete project lifecycle from initial concept development through operational handover, providing clients with comprehensive support that minimizes implementation risks while ensuring adherence to quality standards and timeline requirements. The turnkey implementation process begins with Detailed Concept Development that translates feasibility study recommendations into specific project plans, design specifications, and implementation roadmaps. This concept development phase incorporates stakeholder input, regulatory requirements, and operational considerations that influence project design and implementation approaches. Regulatory Clearance and Compliance Management addresses the complex administrative requirements associated with manufacturing project development across diverse regulatory environments. Our regulatory expertise encompasses licensing procedures, environmental compliance, safety regulations, and quality standards that must be addressed throughout the implementation process.

Facility Design and Engineering Services provide comprehensive technical specifications for manufacturing facilities that optimize operational efficiency while meeting regulatory requirements and industry standards. Our design approach incorporates Industry 4.0 technologies, sustainability considerations, and future expansion possibilities that enhance long-term project value. Procurement and Construction Management coordinates the acquisition of equipment, materials, and services required for project implementation while ensuring adherence to quality standards, cost parameters, and timeline requirements. Our procurement approach leverages global supplier networks while prioritizing local content requirements and regional partnership opportunities. Workforce Development and Onboarding Services address the human capital requirements associated with manufacturing operations, including recruitment strategies, training program development, and organizational structure design that ensure operational readiness and sustainable performance. The Operational Handover Process includes comprehensive testing, commissioning, and knowledge transfer activities that ensure smooth transition from construction to operations while building internal capacity for ongoing management and optimization. Our Competitive Advantage In Turnkey Implementation stems from the integration of artificial intelligence project management dashboards with experienced execution teams that provide real-time visibility into project progress while enabling proactive risk management and optimization opportunities.

Step 03

Industrial Facility Layout and Design Optimization

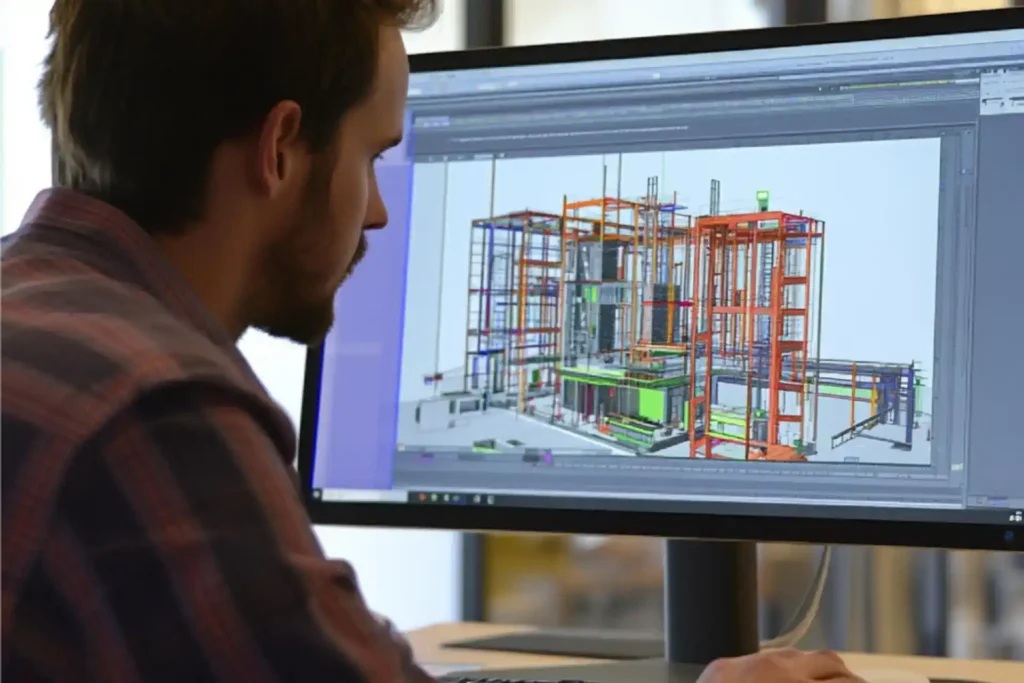

Our facility layout and design services optimize manufacturing operations through systematic analysis of production workflows, space utilization, and operational efficiency considerations that enhance productivity while ensuring safety and regulatory compliance. The facility design process begins with comprehensive site surveys that assess physical constraints, infrastructure availability, and environmental considerations that influence facility layout and design decisions. This site analysis incorporates geotechnical assessments, utility availability, transportation access, and expansion possibilities that affect long-term operational viability. Layout simulation and optimization utilizes advanced modeling tools to evaluate alternative facility configurations and identify optimal arrangements that maximize operational efficiency while minimizing costs and implementation complexity. Our simulation approach incorporates production volume projections, workflow analysis, and equipment specifications that influence layout decisions.

Workflow analysis examines production processes, material handling requirements, and operational procedures to identify optimization opportunities and eliminate inefficiencies that could impact productivity and cost performance. This analysis encompasses both current state assessment and future state design that accommodates growth and technological advancement. Utility planning addresses the infrastructure requirements associated with manufacturing operations, including electrical systems, water and wastewater management, compressed air systems, and specialized utilities required for specific production processes. Our utility planning ensures adequate capacity while optimizing energy efficiency and operational costs. Health, safety, and environmental integration ensures that facility designs meet regulatory requirements while promoting worker safety and environmental protection. Our HSE integration encompasses emergency response planning, waste management systems, and environmental monitoring capabilities that ensure sustainable operations. Our facility designs are specifically tailored for Industry 4.0 readiness, incorporating digital infrastructure, automation capabilities, and data collection systems that enable future technological upgrades and operational optimization. This forward-looking approach ensures that facilities remain competitive as technology continues to evolve.

Step 04

Smart Factory and Automation Planning

Our smart factory consulting services support clients in transitioning from traditional manufacturing approaches to intelligent, automated, and AI-assisted production systems that enhance efficiency, quality, and competitiveness in global markets. The smart factory transformation process begins with comprehensive readiness audits that assess current technological capabilities, organizational readiness, and infrastructure requirements for automation implementation. This assessment identifies gaps and opportunities while developing realistic transformation roadmaps that align with organizational capabilities and market requirements. Technology selection and integration planning addresses the complex decisions associated with automation system design, equipment selection, and software platform integration that determine smart factory effectiveness. Our technology planning encompasses production automation, quality control systems, predictive maintenance capabilities, and data analytics platforms that enable intelligent operations.

Vendor integration and partnership development coordinates relationships with technology suppliers, system integrators, and service providers required for successful smart factory implementation. Our vendor management approach ensures compatibility, reliability, and ongoing support while optimizing costs and implementation timelines. Artificial intelligence adoption roadmaps provide structured approaches for integrating AI capabilities into manufacturing operations, including predictive analytics, quality optimization, production planning, and maintenance scheduling that enhance operational performance. Our AI integration approach emphasizes practical applications that generate measurable value while building organizational capacity for ongoing innovation. The transformation planning process includes change management strategies, workforce development programs, and performance measurement systems that ensure successful adoption of smart factory technologies while maintaining operational continuity during transition periods.

Step 05

Supply Chain and Operational Optimization

Our supply chain optimization services address the complex challenges associated with material sourcing, inventory management, production scheduling, and distribution that influence manufacturing competitiveness and profitability. The optimization process begins with comprehensive data collection and analysis that examines current supply chain performance, identifies bottlenecks and inefficiencies, and quantifies improvement opportunities. This analysis encompasses supplier performance, inventory levels, production scheduling, and distribution effectiveness that impact overall operational performance. Bottleneck diagnosis utilizes advanced analytical tools to identify constraints and limitations that restrict operational efficiency and develop targeted solutions that address root causes rather than symptoms. Our diagnostic approach examines both physical constraints and process limitations that impact performance.

Solution prototyping and testing enables validation of improvement strategies before full-scale implementation, minimizing risks while ensuring that proposed solutions generate expected benefits. Our prototyping approach includes pilot testing, performance measurement, and iterative refinement that optimize solution effectiveness. Standard operating procedure development creates documented processes and procedures that ensure consistent implementation of optimization strategies while building organizational capacity for ongoing improvement. Our SOP development encompasses training materials, performance metrics, and quality control procedures that support sustainable improvement. Impact tracking and continuous improvement monitoring ensures that optimization initiatives generate sustained benefits while identifying additional improvement opportunities. Our tracking approach includes key performance indicators, regular assessments, and adjustment mechanisms that maintain optimization momentum. Our supply chain optimization results typically achieve 15-20% cost savings and 25% efficiency improvements, demonstrating the significant value potential of systematic optimization approaches applied to manufacturing operations.

Step 06

Regulatory and Quality Compliance Support

Our regulatory compliance services ensure that manufacturing operations meet regional and international certification requirements while maintaining operational efficiency and cost effectiveness. The compliance process begins with comprehensive gap analysis that compares current practices with regulatory requirements and industry standards, identifying areas requiring improvement and developing implementation priorities. This analysis encompasses quality management systems, environmental compliance, safety regulations, and industry-specific requirements that influence operational practices. Compliance training and capacity building programs develop internal expertise and ensure that organizational personnel understand regulatory requirements and implementation procedures. Our training approach includes technical training, management system development, and ongoing support that builds sustainable compliance capabilities.

Documentation development and management creates the policies, procedures, and records required for regulatory compliance while ensuring that documentation systems support operational efficiency rather than creating administrative burdens. Our documentation approach emphasizes practical applicability and ease of maintenance. Audit preparation and support services help organizations prepare for regulatory inspections and certification assessments while building confidence in compliance systems and procedures. Our audit support includes mock audits, corrective action planning, and ongoing monitoring that ensures readiness for formal assessments. Our regulatory expertise encompasses ISO quality management standards, Good Manufacturing Practice requirements, Hazard Analysis and Critical Control Points systems, and local regulatory frameworks across Gulf and African markets. This comprehensive expertise ensures that clients achieve compliance while maintaining operational flexibility and efficiency.

Step 07

AI-Driven Production Planning and Optimization

Our artificial intelligence production planning services implement predictive and real-time planning systems that optimize manufacturing operations through advanced analytics and intelligent automation. The AI implementation process begins with data infrastructure development that creates the foundation for intelligent systems through data collection, storage, and processing capabilities that enable advanced analytics. This infrastructure development encompasses sensor networks, data integration platforms, and analytical tools that support AI applications. AI model training and development creates predictive algorithms and optimization systems that address specific manufacturing challenges and opportunities. Our AI development approach emphasizes practical applications that generate measurable value while building organizational capacity for ongoing innovation and improvement. Key performance indicator dashboards provide real-time visibility into manufacturing performance while enabling proactive management and optimization decisions. Our dashboard development creates user-friendly interfaces that present complex information in actionable formats that support effective decision-making.

Staff training and change management ensures that organizational personnel can effectively utilize AI systems while adapting to new operational approaches and decision-making processes. Our training approach emphasizes practical application and ongoing support that builds confidence and competence in AI utilization. The benefits of AI-driven production planning include reduced inventory requirements, faster response times to market changes, improved quality control, and enhanced operational efficiency that provide sustainable competitive advantages in dynamic market environments.

have anything to ask ? Contact us any time.